The advent of robotics and artificial intelligence (AI) in manufacturing marks a transformative era, not just for production processes, but also for the workforce behind them. As the industry stands on the brink of a new age, it’s crucial to understand the multifaceted role of robotics, the economic implications, and the opportunities that lie ahead for talent in this sector. This article sheds light on the symbiotic relationship between human workers and AI, the economic shifts anticipated with the integration of robotics, and the strategic moves required to thrive in the AI-manufacturing landscape.

Key Takeaways

- AI and robotics are augmenting the manufacturing workforce, leading to a demand for upskilling and creating new career opportunities at the technology-production interface.

- Robotics in manufacturing is debunking the myth of workforce replacement by creating new job categories and emphasizing the role of education for a roboticized economy.

- AI advancements are enhancing manufacturing quality and efficiency, with predictive maintenance, AI-enhanced quality control, and optimized supply chains.

- Manufacturers must navigate legal and ethical considerations, including challenges related to AI deployment, data privacy, and security in the evolving manufacturing sector.

- Investing in talent and infrastructure is key to leveraging AI in manufacturing, requiring a skilled workforce, infrastructure upgrades, and a commitment to continuous innovation.

Integrating AI and Robotics into the Manufacturing Workforce

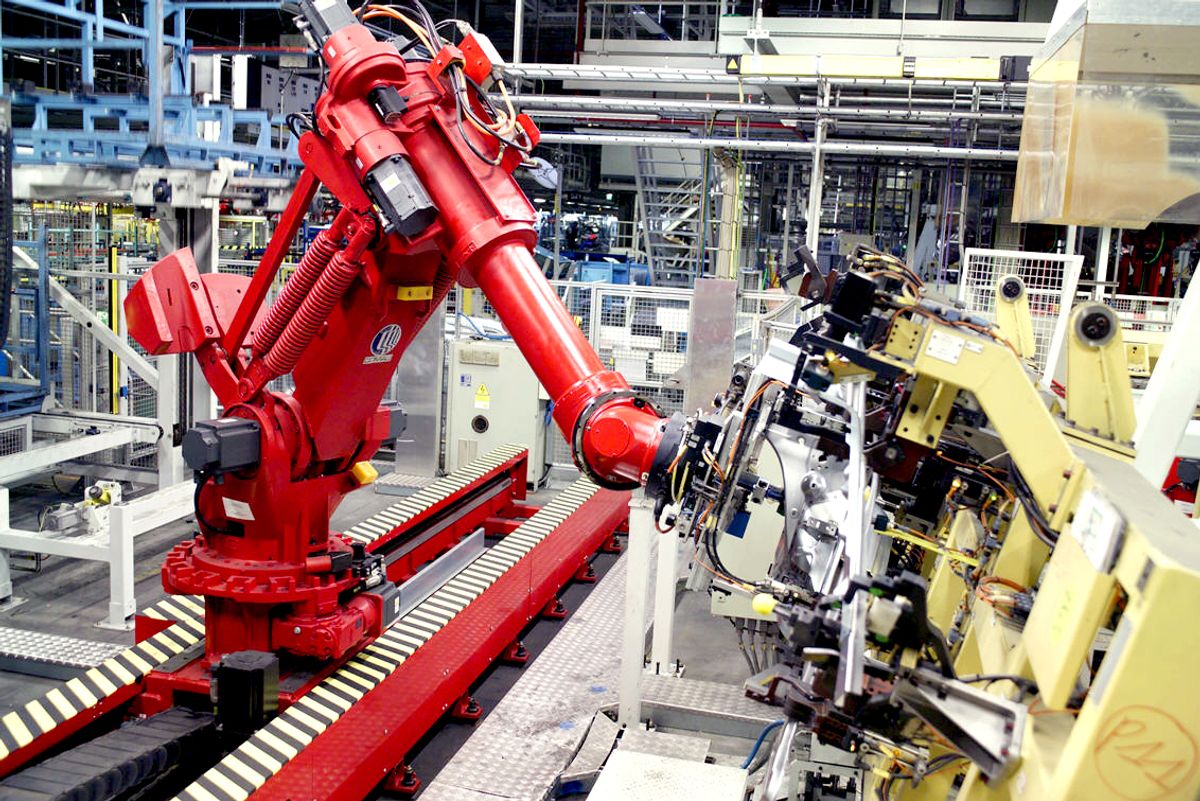

The Synergy of Human Talent and Machine Precision

The integration of AI and robotics into manufacturing is not about replacing human workers but enhancing their capabilities. The symbiosis of human talent and machine precision creates opportunities for augmentation, where AI tools now assist in decision-making and complex tasks. This partnership leverages the strengths of both humans and machines, leading to unprecedented levels of productivity and innovation.

The virtuous cycle of interactions between humans, automation, and machine learning processes is catalyzed by human insight, driving continuous improvement across the manufacturing floor.

Manufacturers who invest in this synergy see a transformation in their workforce. Skilled employees become orchestrators of technology, guiding and optimizing robotic systems to achieve goals that were once unattainable. The table below illustrates the shift in roles and responsibilities:

| Traditional Role | Evolving Role |

|---|---|

| Manual Operator | System Supervisor |

| Quality Checker | Process Optimizer |

| Assembly Worker | Robotic Coordinator |

Embracing this new frontier requires a commitment to ongoing learning and adaptation. As the manufacturing landscape evolves, so too must the skills and approaches of its workforce.

Upskilling for the AI-Driven Manufacturing Landscape

As the manufacturing sector increasingly adopts artificial intelligence (AI), the demand for a workforce proficient in AI and robotics is surging. Upskilling existing employees is crucial to meet the evolving requirements of smart factories. This process involves not only technical training but also fostering an adaptive mindset capable of working alongside advanced AI systems.

To ensure a smooth transition into AI-driven manufacturing, a structured upskilling program is essential. Such programs might include:

- Comprehensive training in data analytics and machine learning principles

- Workshops on operating and maintaining robotic equipment

- Courses on AI integration in supply chain management

- Development of problem-solving and critical thinking skills

By investing in upskilling initiatives, manufacturers can bridge the talent gap and empower their workforce to excel in a high-tech environment. This investment not only enhances productivity but also ensures that human workers remain an integral part of the manufacturing ecosystem, complementing the precision and efficiency of machines.

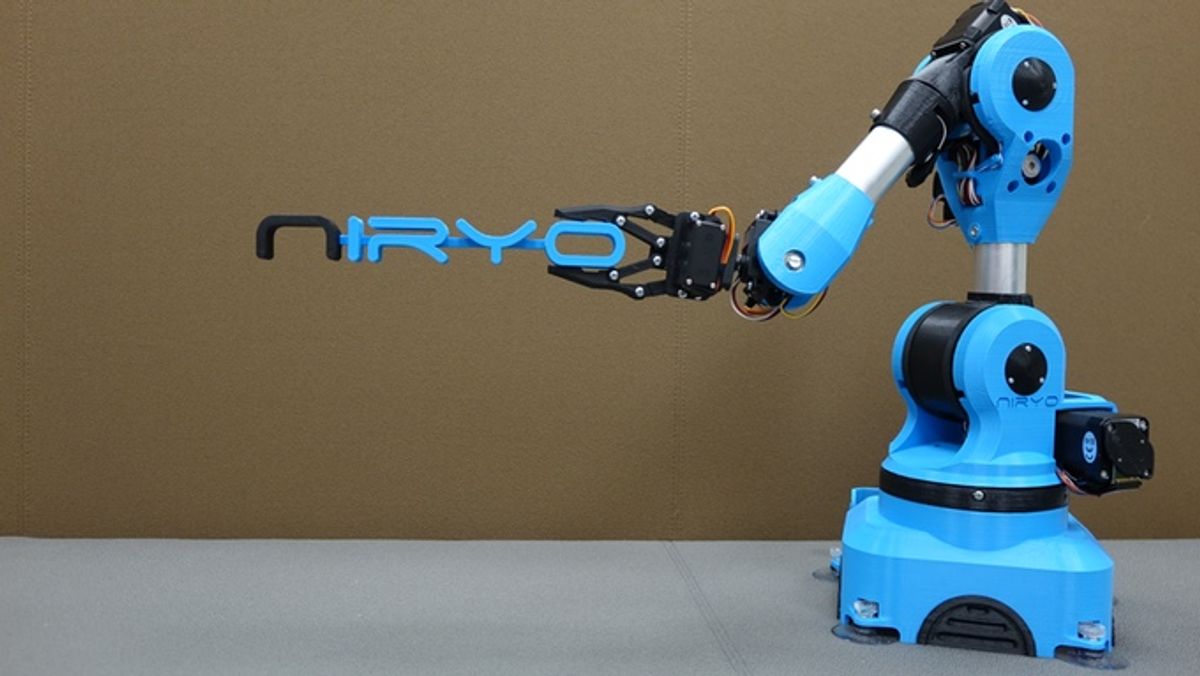

Career Opportunities at the Intersection of Technology and Production

The fusion of technology and production has given rise to a wealth of career opportunities that blend the best of both worlds. Professionals with a knack for innovation and a passion for manufacturing are finding their niche in roles that require both technical acumen and production savvy.

- Engineering: Hone your technical expertise in roles like Automation Systems Engineer, Lead Computational Geometry Software Engineer, and Mechanical Engineer.

- Software Development: Shape the future of manufacturing with positions like MLOps and Data Engineer, Robotics Software Engineer, Senior Robotics Software Engineer, and Software Engineer, Application Infrastructure.

The landscape of manufacturing careers is evolving, with a significant emphasis on roles that leverage both technological proficiency and an understanding of production dynamics. This shift is not just creating jobs but is also enhancing the quality and efficiency of the manufacturing process.

Companies like Bolt-on Recruitment are at the forefront of this transformation, connecting businesses with the talent needed to thrive in this new era. Whether you’re looking to advance your career or are just starting out, the opportunities are vast and varied, spanning from problem-solving to production planning and beyond.

The Economic Impact of Robotics on Manufacturing Jobs

Debunking the Myth of Workforce Replacement

The integration of AI and robotics in manufacturing has sparked a debate centered on the fear of job displacement. However, the reality is more nuanced. Collaborative robots, or ‘cobots’, are designed to work alongside humans, enhancing their capabilities rather than replacing them. These cobots take on repetitive tasks, allowing human workers to focus on more complex and creative aspects of manufacturing.

The narrative that AI and robotics will lead to mass unemployment in manufacturing is being challenged by evidence of workforce augmentation. AI-enabled tools are not only improving productivity but also job satisfaction by providing workers with decision support and actionable insights.

The experience of companies like Ultradent reveals a different story. Despite the integration of advanced automation, they report no net decrease in employment or layoffs. This suggests that the relationship between robotics and employment is not one of replacement but of transformation. Here’s how the workforce is evolving:

- Upskilling: Workers are learning to operate new AI-powered tools and machinery.

- New Roles: As some tasks become automated, new job categories are emerging in robot maintenance, programming, and supervision.

- Collaboration: Humans and machines are working together more closely than ever, each complementing the other’s strengths.

The fears of AI and robotics rendering human workers obsolete are not reflected in the current trends of manufacturing employment. Instead, we are witnessing a shift towards a more collaborative and technologically integrated workforce.

How Robotics Create New Job Categories

The integration of robotics into manufacturing has led to the emergence of new job categories that blend technical expertise with innovative thinking. As robots take on repetitive and hazardous tasks, they free up human workers to focus on more complex and creative aspects of production.

Robotics have burgeoned beyond traditional manufacturing floors, now deployed in a wide range of processes and sectors such as orthopedic, radiological, and surgical applications. This expansion is not only transforming the industry but also creating a demand for a diverse set of skills and roles.

The rise in robot density signifies a shift in the workforce dynamic, necessitating a new breed of talent adept in robotics and automation.

For instance, Machine Labs offers opportunities for engineers, software developers, and skilled production professionals, indicating the variety of roles that robotics has introduced. The success of companies at the core of robotics and automation underscores the potential for job growth in this field.

As robotics become more accessible, there’s a convergence of new tools and technologies, attracting individuals with cross-training and experience in these areas. This is a stark contrast to the situation a decade ago, highlighting the rapid evolution of the manufacturing landscape.

The Role of Education in Preparing for a Roboticized Economy

As the manufacturing sector evolves with the integration of AI and robotics, the role of education becomes pivotal in bridging the skills gap. Educational institutions must adapt their curricula to include robotics and AI training, ensuring that the workforce is equipped for the technological advancements shaping the industry.

The transition to a roboticized economy necessitates a multifaceted approach to education:

- Developing foundational knowledge in STEM fields to understand the principles behind AI and robotics.

- Offering specialized training programs that focus on the operation and maintenance of robotic systems.

- Encouraging interdisciplinary studies that blend technology with business, ethics, and design thinking.

The synergy between advanced robotics and human ingenuity can only be realized when education systems proactively foster the necessary skills and knowledge.

It is essential to recognize that the integration of robotics in manufacturing creates a dynamic where humans and machines collaborate to achieve higher efficiency and quality. This collaboration requires a workforce that is not only technically proficient but also adaptable and continuous learners.

Advancing Manufacturing Quality and Efficiency with AI

The Role of Predictive Maintenance in Reducing Downtime

In the realm of manufacturing, predictive maintenance stands as a critical component in minimizing operational interruptions. By leveraging advanced analytics, manufacturers can anticipate equipment failures before they occur, scheduling repairs during non-peak hours to avoid costly downtime.

The integration of predictive maintenance strategies has shown a marked reduction in unplanned stoppages. This proactive approach not only extends the lifespan of machinery but also enhances overall production efficiency. Below is a list of key predictive maintenance capabilities:

- Predictive Analytics for Maintenance

- Predictive Maintenance-driven Scheduling

- Proactive Issue Identification

- Proactive Problem Solving

Predictive maintenance transforms the traditional reactive maintenance model, fostering a culture of continuous improvement and operational excellence within the manufacturing sector.

AI-Enhanced Quality Control Processes

In the realm of manufacturing, AI-enhanced quality control processes are revolutionizing the way products are inspected and validated. Computer vision and machine learning algorithms work in tandem to scrutinize products with a level of precision that far surpasses human capabilities. This technological synergy not only elevates product quality but also streamlines the inspection process, leading to significant gains in efficiency.

The integration of AI in quality control has led to a transformative shift in manufacturing, where the emphasis on defect detection and prevention is paramount. By leveraging AI, manufacturers are able to proactively address quality issues, often before they arise, ensuring a consistently high standard of output.

The benefits of AI in quality control are multifaceted, encompassing everything from enhanced data accuracy to predictive analytics. Here is a succinct list of advantages:

- Enhanced Quality Assurance

- Improved Collaboration Across Teams

- Minimized Lead Times

- Reduced Manual Effort

- Scalability and Adaptability

These improvements are not just theoretical; they are tangible enhancements that redefine what is possible in manufacturing quality control.

Optimizing Supply Chains Through Intelligent Automation

Intelligent automation is revolutionizing supply chain management by enhancing efficiency and accuracy. AI-driven systems are capable of analyzing complex data to optimize inventory planning, demand forecasting, and logistics routes. This leads to a more agile and responsive supply chain, capable of adapting to market changes with unprecedented speed.

The role of AI in supply chain optimization encompasses both benefits and challenges. By using robotics, autonomous vehicles, and intelligent picking systems, AI can enhance efficiency, improve order fulfillment processes, and minimize errors.

The following list outlines key areas where AI contributes to supply chain optimization:

- Real-time insights into demand and inventory management

- Strategic recommendations for cost reduction

- Enhanced logistics optimization

- Risk mitigation through predictive analytics

These advancements not only streamline operations but also support the strategic allocation of resources, ensuring that every aspect of the supply chain is operating at peak performance.

Navigating the Legal and Ethical Terrain of Manufacturing AI

Anticipating and Addressing Legal Challenges in Robotics

As the manufacturing sector increasingly integrates AI and robotics, a complex legal landscape emerges. Manufacturers must grapple with issues such as liability for accidents caused by design limitations and ensure compliance with evolving regulations. Proactive measures are essential to address these challenges effectively.

- Data privacy and security are paramount as AI systems handle sensitive information.

- Establishing clear guidelines for accountability is crucial in the event of AI-related errors or accidents.

- Ensuring AI systems adhere to safety standards and regulatory requirements mitigates legal risks.

The deployment of AI in manufacturing necessitates a thorough understanding of legal requirements and ethical considerations to maintain trust and accountability.

Manufacturers must also consider the ethical implications of AI, including bias mitigation and transparency in decision-making algorithms. These considerations are not just about compliance but about building a foundation of trust with consumers and the workforce.

Ethical Considerations in AI Deployment

The integration of AI into manufacturing processes necessitates a careful examination of ethical considerations. Manufacturers must grapple with questions of bias, fairness, and transparency in AI algorithms. Ethical AI principles, such as fairness, accountability, and transparency (FAT), should guide the development and deployment of AI systems to uphold ethical standards and social responsibility.

In the event of AI-related errors or accidents, the issue of liability and accountability becomes paramount. Clear guidelines for accountability must be established, ensuring that AI systems adhere to safety standards and regulatory requirements to mitigate legal risks.

The interconnected nature of smart factories creates vulnerabilities that malicious actors may exploit. Robust cybersecurity measures and data governance frameworks are essential to safeguard sensitive information and maintain trust among stakeholders.

Furthermore, regulatory compliance is a significant aspect of ethical AI deployment. Manufacturers are obligated to ensure that AI systems adhere to industry standards and legal requirements regarding safety, environmental impact, and labor practices. This includes addressing concerns such as bias mitigation and transparency in decision-making algorithms, which are crucial for fostering trust and accountability.

Data Privacy and Security in an AI-Enabled Manufacturing Sector

In the age of AI-enabled manufacturing, data privacy and security are paramount. The integration of AI systems necessitates stringent measures to protect sensitive information from unauthorized access and potential breaches. Compliance with data protection laws, such as the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA), is not just a legal obligation but a cornerstone of consumer trust.

The adoption of AI in manufacturing brings with it a complex web of legal and ethical challenges. Manufacturers must navigate these carefully to maintain integrity and stakeholder confidence.

To ensure robust data governance, a multi-layered approach is often adopted, involving:

- Regular audits and updates to security protocols

- Employee training on data handling and privacy policies

- Implementation of advanced encryption and access control systems

Furthermore, anticipating and preparing for legal challenges is crucial. Manufacturers must stay abreast of evolving regulations and adapt their practices accordingly to mitigate risks associated with data privacy and security.

Investing in the Future: Talent and Infrastructure for AI Manufacturing

Building a Skilled Workforce for Tomorrow’s Factories

As the manufacturing landscape evolves with the integration of AI and robotics, the demand for a skilled workforce is becoming increasingly critical. Investing in the development of talent is not just a necessity but a strategic move to ensure the longevity and competitiveness of the manufacturing sector. The challenge is twofold: bridging the manufacturing skills gap and competing with other industries for AI-savvy professionals.

To address these challenges, a multi-pronged approach is essential:

- Reskilling and upskilling current employees to keep pace with technological advancements.

- Attracting new talent by showcasing the innovative and technologically advanced nature of modern manufacturing.

- Creating partnerships with educational institutions to develop curricula that align with industry needs.

- Offering apprenticeships and internships to provide hands-on experience with AI and robotics.

The urgency to cultivate a workforce adept in AI and robotics is underscored by the projected need for millions of jobs to be filled in the near future. This is not just about filling positions, but about fostering an environment where knowledge transfer and continuous learning are paramount.

The table below illustrates the stark reality of the skills gap in the manufacturing sector:

| Year | Projected Jobs Needed | Current Shortfall |

|---|---|---|

| 2024 | 3.8 million | 71% of CEOs report difficulty in hiring |

As we look towards building the factories of tomorrow, it is clear that a concerted effort in developing a skilled workforce is the cornerstone of thriving in an AI-driven manufacturing world.

Infrastructure Upgrades for Seamless AI Integration

To fully harness the potential of AI in manufacturing, significant investments in both talent and infrastructure are imperative. Upgrading legacy systems and integrating AI-compatible technologies are critical steps in laying the foundation for a future-ready manufacturing ecosystem. These upgrades often involve substantial financial commitments, with costs varying based on company size and the specific initiatives undertaken.

For a seamless transition to AI-driven manufacturing, businesses must consider:

- The acquisition and implementation of advanced software and MES systems.

- The installation of data collectors, such as sensors, to facilitate real-time data analysis.

- Ensuring regular maintenance and updates to keep systems operational and secure.

- Training employees to proficiently utilize new technologies, fostering a culture of continuous learning.

By investing in the right infrastructure, manufacturers can unlock new levels of efficiency and innovation, ultimately driving a stronger return on investment.

The rapid advancements in AI have reduced the time required for task automation from weeks to less than 24 hours, marking a significant inflection point in the capability of autonomous systems. This acceleration underscores the importance of infrastructure that can support quick adaptation and scaling of new tasks.

The Strategic Importance of Continuous Innovation and Learning

In the rapidly evolving landscape of AI manufacturing, continuous innovation and learning are not just beneficial; they are imperative for survival. The integration of new technologies and methodologies requires a workforce that is adaptable and skilled in the latest advancements.

To maintain a competitive edge, companies must foster an environment where innovation is encouraged and learning is an ongoing process. This involves investing in training programs, embracing a culture of knowledge sharing, and providing opportunities for employees to engage with cutting-edge technologies.

- Embrace a culture of knowledge sharing

- Invest in employee training programs

- Engage with cutting-edge technologies

The commitment to continuous innovation and learning is the cornerstone of a future-proof manufacturing sector. It ensures that both the workforce and the production processes remain at the forefront of efficiency and quality.

Embracing the Future: Robotics and Talent in Manufacturing

The integration of robotics into manufacturing marks a transformative era, not just for the industry, but for the workforce as well. As we’ve explored, the rise of AI and robotics is not a harbinger of job displacement, but rather an opportunity for workforce augmentation and talent development. Companies like Machine Labs are at the vanguard, offering exciting career opportunities for those ready to join the manufacturing revolution. The future of manufacturing is one of enhanced efficiency, quality, and productivity, underpinned by a symbiotic relationship between human ingenuity and robotic precision. It is imperative for manufacturers to invest in both the technology and the talent that will drive this innovation forward. As we anticipate the legal and ethical challenges ahead, it is clear that the role of robotics in manufacturing is not just about the machines—it’s about the people who make them work and the collective progress they represent.

Frequently Asked Questions

How is AI and robotics integration impacting the manufacturing workforce?

AI and robotics integration is augmenting the manufacturing workforce by enhancing human capabilities, not replacing them. Collaborative robots, or ‘cobots,’ work alongside human operators to handle repetitive tasks and improve ergonomics, while AI-enabled tools provide actionable insights and decision support, boosting productivity and job satisfaction.

What new career opportunities are emerging at the intersection of technology and production?

New career opportunities include roles such as Robotics Software Engineer, AI Data Scientist, Manufacturing Technician, Production Field Service Technician, and Quality Manager. These positions are crucial for driving innovation and maximizing the efficiency and productivity of manufacturing operations.

What is the role of education in preparing for a roboticized economy?

Education plays a vital role in preparing for a roboticized economy by equipping individuals with the necessary skills in data science, machine learning, robotics, and other relevant fields. This allows them to adapt to new technologies and capitalize on the opportunities created by AI and robotics in manufacturing.

How does predictive maintenance contribute to manufacturing quality and efficiency?

Predictive maintenance uses AI and data analytics to anticipate equipment failures before they occur, reducing downtime and maintenance costs. This proactive approach ensures that manufacturing operations run smoothly and efficiently, while also maintaining high-quality production standards.

What are the legal and ethical considerations when deploying AI in manufacturing?

Legal and ethical considerations include ensuring compliance with regulations, addressing potential biases in AI algorithms, maintaining data privacy and security, and considering the impact of automation on employment. Manufacturers must anticipate and address these challenges to responsibly deploy AI technologies.

Why is continuous innovation and learning important for AI manufacturing?

Continuous innovation and learning are crucial for AI manufacturing to stay competitive and adapt to rapid technological advancements. Investing in talent development and infrastructure upgrades helps manufacturers leverage AI’s full potential and maintain a future-ready, innovative manufacturing ecosystem.